Why Your Cutting Fluid Foams and Proven Solutions

Cutting Fluid Foaming Issues in CNC Machining? 5 Root Causes & Proven Solutions from Industry Experts

Foaming in metal machining is a costly and often overlooked issue.

When coolant foam affects your CNC lathe or milling machine, it can reduce machining quality, shorten tool life, and destabilize equipment.

Based on Hai Lu Jya He’s decades of field experience, this guide reveals the five most common causes of coolant foaming—and how to fix them fast.

The Problem Diagnosis: 5 Reasons Your Coolant Tank Is Foaming

To stop foaming for good, you first need to know what causes it. Here are the top factors we’ve found through years of field experience:

1. Limited Coolant Tank Space (Circulation Issue)

■ The Cause: Too little coolant or a poorly designed tank prevents air from settling. With high-pressure pumps, air can be recirculated before it escapes.

■ Impact: Foam forms on the surface and becomes stabilized, leading to overflow and aeration.

2. Accumulation of Chips and Debris (Filtration Blockage)

■ The Cause: Metal chips, fines, and tramp oil are not regularly removed. These contaminants can block drain holes, disrupt the smooth return of the coolant, and act as foam stabilizers.

■ Impact: Coolant flow is compromised, accelerating foam formation and making operations unstable.

3. Excessive Water Pressure or Improper Return Flow Angle

■ The Cause: High-velocity or high-pressure fluid return causes the coolant to violently crash onto the liquid surface in the tank. This turbulent action mechanically mixes large amounts of air into the fluid.

■ Impact: Stable, persistent foam forms quickly, especially in systems utilizing high-pressure nozzles.

4. Prolonged Machining Time & Fluid Degradation (Chemical Change)

■ The Cause: Heat, bacteria, and contamination can break down cutting fluid additives, reducing their anti-foaming effectiveness.

■ Impact: The fluid’s inherent defoaming capacity is reduced, making it difficult to control foam, especially during extended operations.

5. High Concentration or Low Fluid Level (Emulsion Instability)

■ The Cause: An overly high oil-to-water ratio (high concentration) or low fluid level in the tank can destabilize the emulsification process. Low levels increase agitation as the pump struggles to draw fluid.

■ Impact: Emulsion instability can increase surface tension, directly leading to severe and persistent foaming problems.

📚 CASE STUDY: Two-Year Foaming Crisis Resolved in One Switch

Client Challenge: A motorcycle customization shop struggled for two years with severe foaming during CNC milling, especially when switching between aluminum and iron. Coolant overflow frequently disrupted work, required constant maintenance, and drove up costs. After consulting our field service team, they switched to MORESCO BS-66 Water Soluble Cutting Oil from Hai Lu Jya He.

MORESCO BS-66 is designed for high-pressure machining and has long-lasting anti-foaming properties. With this change, the client no longer experienced overflowing coolant, reduced costly fluid loss with chips, and enjoyed smoother workflow and more stable production.

ACTIONABLE SOLUTIONS: How to Effectively Reduce Foaming

Below are the most practical and effective methods recommended by our service team for resolving foam issues, focusing on system integrity and fluid management.

A. Optimize Tank Design and Fluid Return:

■ Ensure the tank is filled to the proper working level.

■ Avoid direct, high-impact fluid return. Install a buffer return pipe, a low-velocity deflector, or an anti-cyclone device to ensure the fluid gently enters below the surface.

B. Implement Regular Cleaning Schedules:

■ Contaminants are foam breeding grounds. Clean the tank and sump weekly to remove chips and debris.

■ Keep all drain holes, screens, and filters clear to ensure unobstructed, laminar flow back to the reservoir.

C. Control System Temperature:

■ Monitor and maintain an optimal coolant temperature. High temperatures can reduce fluid viscosity and accelerate the depletion of anti-foam agents, significantly increasing foam stability, especially in synthetic fluids.

D. Test and Adjust Water Quality:

■ Soft water (low mineral content) can often be the primary culprit, leading to increased foaming, particularly when new fluids are introduced.

■ Consult your fluid supplier. Adjusting water hardness or utilizing quality de-ionized water can help minimize foaming potential.

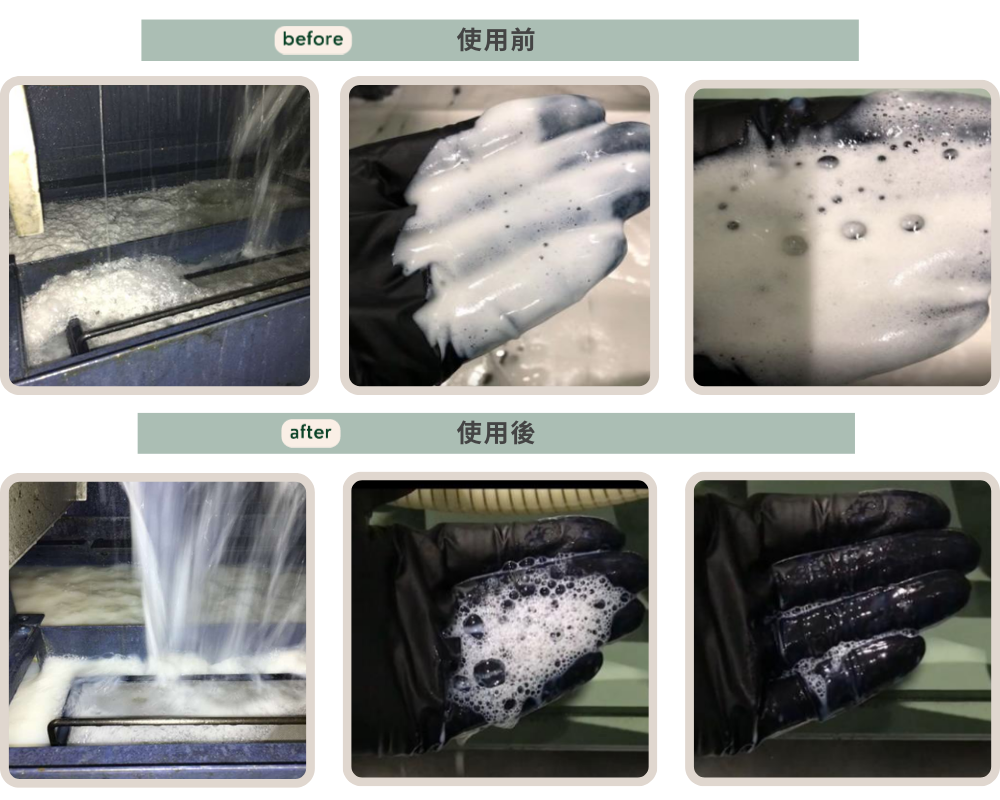

E. Evaluate Fluid Performance (The Quick Shake Test):Perform a simple test: Shake a sample of the cutting fluid vigorously for 10 seconds.

■ Result 1 (Good Fluid): If the foam dissipates quickly, the fluid's formulation is stable. The issue is likely mechanical or related to water quality/concentration.

■ Result 2 (Poor Performance): If the foam remains stable and does not dissipate, the fluid itself has insufficient defoaming capability and needs to be replaced.

☎️ Need Personalized Advice? +886-25332210

Contact our technical team today for a free consultation and personalized recommendation tailored to your specific equipment and operating conditions. Fill out the form below to connect with a specialist!

- Recommend Product

MORESCO Water Soluble Cutting Oil

MORESCO BS-66 Chlorine-Free Eco Soluble Cutting Oil

MORESCO TOOLMATE BS-66 is a high-performance, bio-static type water-soluble cutting fluid designed...

Details- Articles

As we know, the concentration of cutting oil is crucial for stable emulsion and optimized lubrication. But, there’s another critical key: WATER QUALITY. Water quality encompasses hardness, pH, mineral...

Read more