Facility & Equipment

Hai Lu Jya He: Precision Cutting Oil Manufacturing & ISO 9001 Quality

Welcome to the core of Hai Lu Jya He (HLJH) - our advanced manufacturing facility for precision industrial lubricants. As specialists in metalworking cutting oils, rust preventive oils, slideway oils, and hydraulic oils, we understand that exceptional quality begins at the source. Our commitment is to a transparent, expert-driven production process that delivers unparalleled reliability to our global partners, all while adhering to the highest standards of environmental stewardship.

Factory & Equipment: Where Expertise Meets Green Technology

Located in the Changhua Quansing Industrial Park, our state-of-the-art facility is the foundation of our product quality. Here, precision manufacturing handles both mass production and highly customized OEM/ODM orders with superior efficiency and consistency. We commit to a sustainable production lifecycle by consistently integrating the principles of Green Chemistry, rigorously working to minimize the use of hazardous substances and reduce the overall environmental footprint throughout our entire manufacturing process.

■ Produced Items:Cutting Fluid, Neat Cutting Oil

■ Monthly Capacity:Up to 150 tons of cutting fluids

■ Global Sales:Taiwan, Japan, China, Vietnam, Indonesia, India, and South America

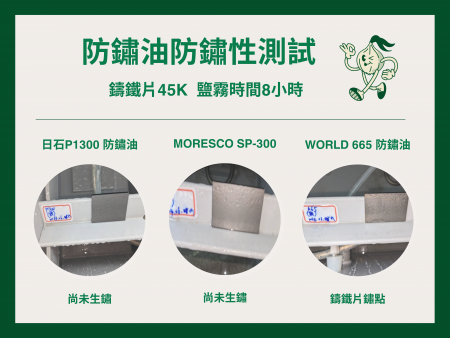

Salt Spray Testing Equipment

Advanced Salt Spray Testing: We utilize our dedicated salt spray chambers to perform accelerated corrosion resistance tests. By simulating harsh environments, we can assess the durability and anti-rust properties of our products in just 24 hours, achieving results that would otherwise take up to a year in natural conditions. This ensures the long-term protection of your equipment.

Anti-Rust Oil Durability Testing (Short, Medium, & Long-Term)

We conduct stringent salt spray testing to validate the performance of our rust preventive oils, including MORESCO SP-300 and WILL W-609, under carefully controlled conditions of 35 °C chamber temperature and 47 °C saturated air tank temperature, with a spray collection rate of 1.6 mL per hour over 8 hours. This rigorous testing ensures that metal components receive reliable short-, medium-, and long-term protection, giving customers confidence in the durability, corrosion resistance, and overall effectiveness of our products. By simulating real-world environmental conditions, HLJH guarantees consistent product quality, optimizes formulations for maximum performance, and delivers solutions tailored to the demands of industrial applications, reinforcing our commitment to excellence in metalworking lubrication.

■ MORESCO Long Term Rust Preventive Oil: MORESCO SP-300

■ WILL Short Term Rust Preventive Oil: WILL W-609

Quality Assurance Laboratory

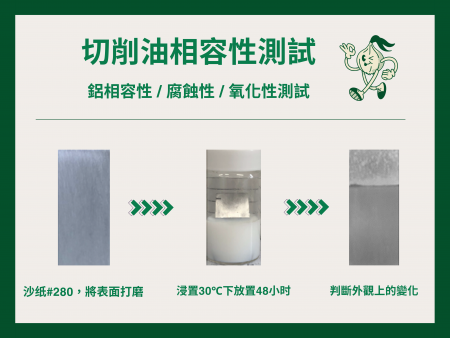

At HLJH, our Quality Assurance Laboratory is dedicated to comprehensive comparative testing of cutting oils and industrial lubricants. We specialize in evaluating critical performance metrics such as anti-rust properties, material compatibility, and tool life, providing clients with reliable, data-backed insights. Through precise data analysis, we generate detailed comparison reports that empower customers to make informed decisions and select the products best suited for their specific machinery and applications. Our laboratory also enables customized OEM/ODM solutions, ensuring each client receives a tailored lubrication system designed to maximize efficiency, performance, and reliability.

Aluminum Compatibility & Corrosion Testing

At HLJH, we perform this aluminum compatibility and corrosion/oxidation test to ensure the safety and non-reactivity of our lubricants with sensitive metals. Aluminum test pieces are first ground and thoroughly cleaned before being partially immersed in a 5% diluted sample of the lubricant. The submerged pieces are then conditioned in a constant-temperature chamber at 30 °C for 48 hours. After immersion, the pieces are carefully inspected for signs of corrosion or oxidation, confirming their compatibility and the protective performance of our products. This procedure represents HLJH’s standardized testing method for evaluating the quality and reliability of our oils.

2026 Tanzi Juxing Industrial Park – New Smart Factory

HLJH is shaping the future of industrial lubrication with a new facility in Tanzi Juxing Industrial Park, expected to be completed in 2026, that integrates office, production, and logistics under one roof. Featuring automated production systems and digital management tools (CRM and Facebook) for streamlined operations, it is designed as a Green Cutting Oil Smart Factory, reflecting our commitment to environmental sustainability and risk reduction, backed by over 40 years of industry experience. HLJH is also expanding its global distribution network and increasing production capacity to ensure reliable delivery worldwide.

🌏 Ready to Optimize Your Operations?

HAI LU JYA HE is more than a manufacturer; we are your expert partner in lubrication, backed by over 40 years of industry experience. Our modern facilities, integrated service model, and dedication to quality and sustainability make us the number one choice for critical manufacturing operations. Furthermore, as an authorized global distributor for MORESCO, we bring world-class Japanese technology directly to you.