Steel Machining Solutions

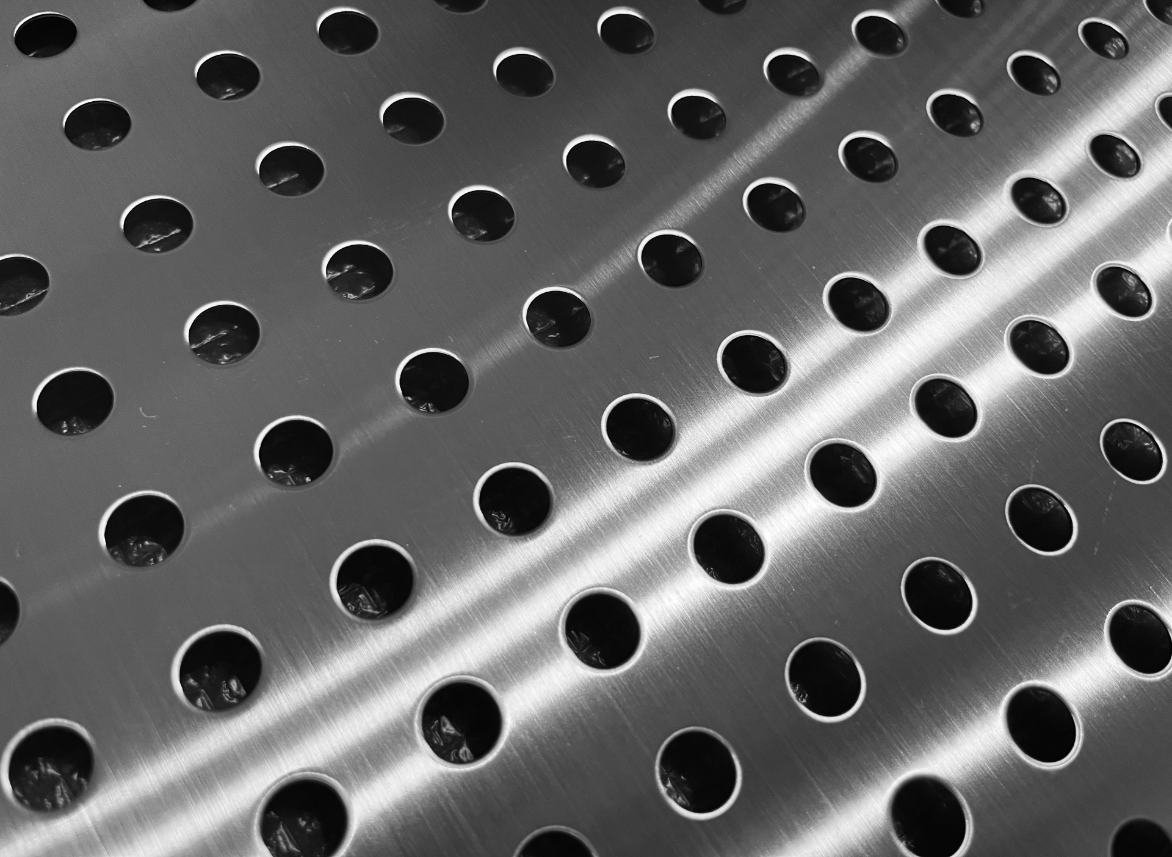

High-Performance Cutting Fluids for Steel Machining

Steel is the backbone of modern manufacturing, but its hardness and heat generation require more than just "any" lubricant. At Hai Lu Jya He (HLJH), we provide specialized cutting fluids designed to handle the rigors of high-speed and heavy-duty steel machining, ensuring your operations run cooler, faster, and longer.

Empowering Key Industries with Precision

- Automotive Industry: Precision grinding and milling of crankshafts, gears, and transmission components.

- Aerospace & Defense: High-tensile alloy machining for structural components requiring zero-defect surfaces.

- Mold & Die Making: Heavy-duty cutting of hardened tool steels and tungsten carbide.

- General Engineering: High-efficiency production of fasteners, hydraulic valves, and mechanical parts.

Optimizing Steel Machining Performance

Steel machining presents critical challenges like intense heat, rapid tool wear, and oil foaming. Our advanced cutting fluids address these head-on by providing superior cooling and an ultra-tough lubrication film. By stabilizing chemical reactions and preventing cobalt leaching, our solutions ensure maximum tool longevity, cleaner operations, and uncompromising precision for every workpiece.

Overcoming the Challenges of Steel Machining

1. Extreme Heat Management

High friction between the tool and workpiece generates intense heat. Our fluids offer superior cooling performance to dissipate heat rapidly, preventing workpiece deformation and tool softening.

2. Tool Wear & Maintenance Costs

The inherent hardness of steel leads to rapid tool degradation. Our formulations provide an ultra-tough lubrication film that reduces friction, significantly extending tool life and reducing downtime.

3. Cobalt Leaching & Foaming

In high-pressure systems, especially with tungsten steel, oil foaming and cobalt leaching can occur. Our synthetic solutions are stabilized to inhibit chemical reactions, keeping your workspace clean and your oil clear.

Choosing the Right Fluid for Peak Performance

Selecting the optimal cutting fluid is the final step in unlocking your machine’s full potential. Based on decades of field experience, we’ve curated a selection of high-performance lubricants tailored for different machining intensities. Explore our recommended products below to find the ideal solution for improving surface finish, reducing cycle times, and optimizing your overall cost-per-part.

Recommended Cutting Oils for Steel Applications

| Application Type | Recommended Product | Key Technical Advantage |

| Difficult-to-Machine Alloys | MORESCO BS-9 | Chlorine-free & eco-friendly; high EP (Extreme Pressure) lubrication. |

| General Purpose / CNC | MORESCO BS-6M (Semi-Synthetic) | Superior balance of cooling and cleanliness for multi-material lines. |

| Heavy-Duty Broaching/Tapping | HLJH NA-308T (Neat Oil) | Maximum lubricity for high-temperature, low-speed heavy cutting. |

Quality You Can Trust: Compliance & Support

- Certified Safety: All products are compliant with EU REACH and RoHS regulations.

- Technical Documentation: Full access to TDS and SDS for every batch.

- Eco-Friendly Formulations: Bacterial-resistant designs that extend fluid life and reduce environmental waste.

Ready to Enhance Your Machining Results?

Whether you are looking to reduce tool costs or improve surface finish, our technical experts are here to help you select the ideal fluid for your steel grade and machine type. ☎️Call Us: +886-4-25332210 Or fill out the online contact form below, and our professional sales team will assist you shortly.

Steel Machining Solutions - High-Performance Cutting Fluids for Steel Machining | Taiwan-Based Metalworking Fluid Manufacturer & Supplier For 39 Years | HLJH

Located in Taiwan, HAI LU JYA HE CO., LTD has been an industrial lubricant manufacturer and supplier. Main products, include Steel Machining Solutions, metalworking fluids, industrial lubricants, soluble cutting oils, semi-synthetic cutting oils, synthetic cutting fluids, neat cutting oils, rust preventive oils, slideway oils and hydraulic oils, which can reach 150 tons of cutting fluids per month.

HAI LU JYA HE Co., Ltd. (HLJH) have been focusing on manufacturing and marketing the industrial lubricants more than 30 years. Our fundamental belief is to make a harmful, friendly with lives, businesses, and leaving a lasting legacy for generations to come. We offer metalworking fluids (water-based cutting fluid, neat cutting oil), rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain. Our fundamental belief is to offer harmful and friendly products such as water-based cutting oils, neat cutting oil, rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain.

HLJH has been offering customers high-quality metalworking oils and fluids, both with advanced technology and 39 years of experience, HLJH ensures each customer's demands are met.