Why Cutting Fluid Separates into Oil and Water – Causes, Risks, and Solutions

Cutting fluid separation—where the mixture splits into distinct oil and water layers—is a common but often misunderstood issue in CNC and metalworking operations. Many users mistake this for normal degradation or assume the fluid is spoiled, but separation is often preventable and correctable.

In this article, we'll explore the causes, risks, and practical solutions for cutting fluid separation to help extend fluid life, reduce machine issues, and lower operating costs.

Here are the most common causes:

• Poor water quality (hard water, high mineral content)

• Contaminants like tramp oil, hydraulic oil, or machining debris

• Incorrect mixing ratio (concentration too high or too low)

• Old or expired cutting fluid

• Lack of circulation or agitation, especially during long idle periods

• Biological growth that alters the pH or destabilizes the emulsion.

Is Separation Dangerous? Why It Matters

Ignoring separation can lead to:

• Reduced lubrication and cooling performance

• Tool wear and surface finish defects

• Increased foam, odor, and bacterial growth

• Coolant system clogs or pump damage

• Unexpected production downtime

Even minor oil-water separation is a red flag that the fluid system needs maintenance or adjustment.

Can Separated Cutting Fluid Be Saved?

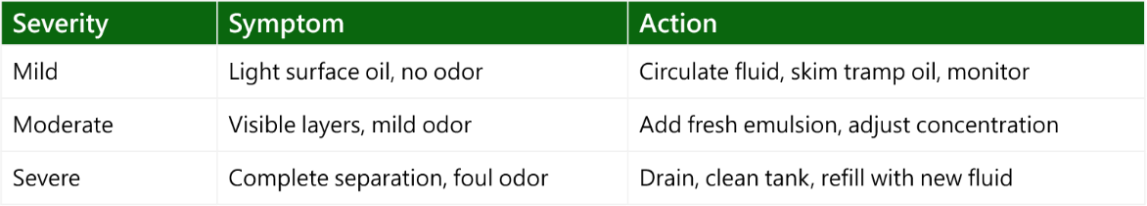

Yes, in many cases. Here’s how to assess and possibly recover it:

If the coolant has a strong smell, sticky residue, or milky sludge, it's best to replace it completely and sanitize the tank.

How to Prevent Oil-Water Separation in Cutting Fluid

To prevent oil-water separation, start by using clean, soft water and always mix cutting fluid using the correct method—add oil into water, never the reverse. Install tramp oil skimmers to remove floating oil, and circulate the fluid regularly to avoid stagnation. Monitor pH, concentration, and clarity frequently, and avoid mixing different brands or fluid types. For better long-term stability, consider using semi-synthetic or fully synthetic cutting fluids.

Recommended Solutions

If your coolant often separates, there are practical solutions to improve fluid stability. Coolant management systems help maintain proper concentration, while automatic mixers ensure consistent blending. Adding tramp oil separators or skimmers removes contamination before it causes emulsion failure. Finally, switching to high-stability cutting fluids—especially chlorine-free and PFAS-free formulas—can significantly reduce separation issues and improve overall coolant life. HLJH provides a full range of cutting fluids and equipment designed to support clean, stable, and efficient machining operations.

Hai Lu Jya He offers a complete line of water-soluble and synthetic cutting fluids designed to resist oil-water separation and maximize machine uptime. Contact us for technical support or product recommendations.

- Articles

As we know, the concentration of cutting oil is crucial for stable emulsion and optimized lubrication. But, there’s another critical key: WATER QUALITY. Water quality encompasses hardness, pH, mineral...

Read moreFoaming in metal machining is a costly and often overlooked issue. When coolant foam affects your CNC lathe or milling machine, it can reduce machining quality, shorten tool life, and destabilize equipment. Based...

Read moreIn CNC environments, seeing smoke or smelling unusual odors is a major red flag for operators. Common questions often arise: "Is our cutting oil toxic?" or "Did we choose the wrong product?"While smoke...

Read more