MORESCO HILUBE High-Temp Lubricants

MORESCO HILUBE is a specialized line of high-performance synthetic lubricants developed by MORESCO, Japan, specifically engineered for equipment operating in extreme heat environments.

MORESCO HILUBE is recognized for its outstanding thermal stability, low-carbon residue properties, and extended lubrication life. A diverse range of viscosities ensures optimal performance for various chains, bearings, and sliding surfaces operating under continuous high stress.

The MORESCO HILUBE Advantage: Engineered for Extreme Heat

MORESCO-HILUBE high-temperature lubricants are formulated using MORESCO’s proprietary ADE special formulation technology. The Diphenyl Ether (ADE) structure provides exceptional chemical stability, high resistance to both oxidation and reduction, resulting in superior heat and oxidation resistance. This crucial stability allows the lubricant to maintain its liquid state and function effectively over prolonged periods at high temperatures.

For the most demanding high-temperature applications, our ester-based products (R-Series) offer long-lasting film life under the thin-film lubrication conditions frequently encountered in real-world operations. Furthermore, the minimal residue after drying helps significantly prolong equipment service life and reduces the frequency of maintenance and downtime.

This advanced lubricant series is widely applied across critical industries, including:

- Food Manufacturing (Ovens, Conveyors)

- Plastic Film Processing (Tenter Frames)

- Material Drying

- Dyeing/Finishing

- Coating Facilities

Why Choose MORESCO HILUBE High-Temperature Lubricants?

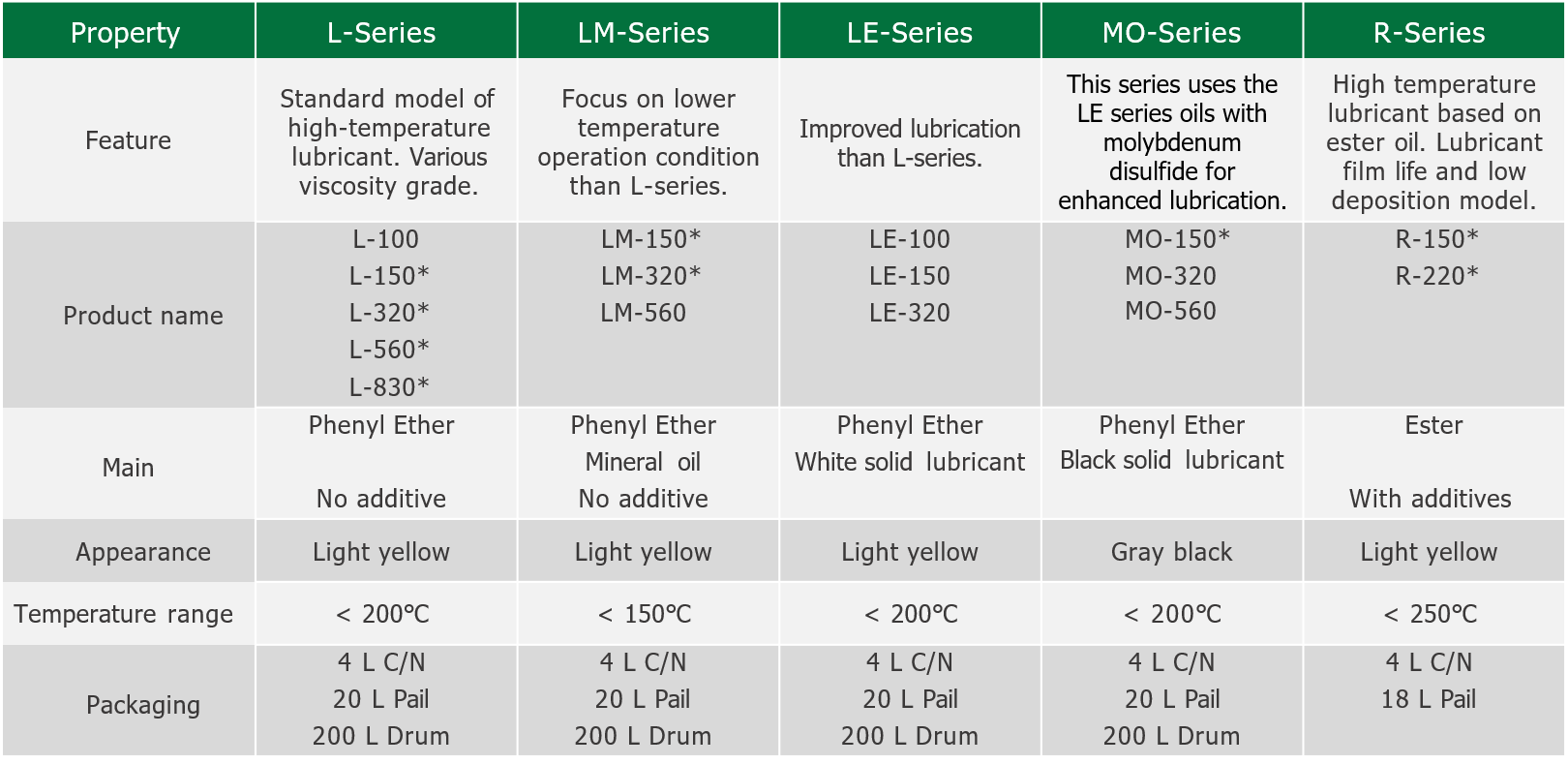

:Feature

Packaging

■ Designed for High-Temp Components: Optimized for chains and sliding parts operating under continuous heat.

■ Food-Grade Options: Select models are NSF H2 Certified (suitable for non-food contact applications in food processing machinery).

■ Extended Service Life: A long-lasting lubrication film effectively lowers maintenance frequency and costs.

■ Flexible Application: Multiple viscosity and temperature grades to meet the diverse needs of various industrial applications.

MORESCO HILUBE Product Series & Selection Guide

Choosing the correct MORESCO-HILUBE grade is crucial for optimal performance and equipment longevity. We recommend evaluating based on these two key indicators:

1. Operating Temperature Range: Select an oil that remains stable, lubricates effectively, and resists deterioration or carbon formation over the actual running temperature.Viscosity Grade: Choose the appropriate Kinematic

2. Viscosity Grade: Select the appropriate Kinematic Viscosity (unit: mm²/s @ 40°C) based on the equipment manufacturer's recommendation or your current oil specifications.

The numerical suffix in the product model indicates its viscosity value at 40°C.

(For example, the kinematic viscosity of model "L-100" is 100 mm²/s @ 40°C.)

Hai Lu Jya He is a trusted Taiwan-based manufacturer specializing in high-performance industrial lubricants with a core commitment to reliable global logistics and on-time delivery. With established distribution networks in the Philippines and Malaysia, we proudly serve a diverse international clientele across India, Vietnam, Thailand, China, Peru, and Colombia.

We are actively expanding our global footprint into the Mexico, USA, and European markets, ensuring our ISO 9001:2016 certified operations meet the highest international quality standards. Backed by full technical support and comprehensive documentation (SDS, TDS, RoHS), we provide our global partners with the consistency, efficiency, and compliance required for modern precision manufacturing.

Looking for guidance? ☎️Call Us: +886-4-25332210

Or fill out the online contact form at the bottom of the product page, and we’ll get back to you as soon as possible.

- Download Files

-

Technical Data Sheet (TDS) of MORESCO L-150

A Technical Data Sheet is a document which describes the technical data of a raw material. It is important for our use of the material in the intended...

DownloadSafety Data Sheet (SDS) of MORESCO L-150

Protect health and security and also a duty to properly label substances on the basis of physio-chemical, health or environmental risk.

Download

MORESCO HILUBE High-Temp Lubricants - MORESCO HILUBE High-Temp Lubricants | Eco-Friendly, Harmless & Low Pollution Industrial Lubricants Manufacturer And Supplier Since 1982 | HLJH

Located in Taiwan, HAI LU JYA HE CO., LTD has been an industrial lubricant manufacturer and supplier. Main products, include MORESCO HILUBE High-Temp Lubricants, metalworking fluids, industrial lubricants, soluble cutting oils, semi-synthetic cutting oils, synthetic cutting fluids, neat cutting oils, rust preventive oils, slideway oils and hydraulic oils, which can reach 150 tons of cutting fluids per month.

HAI LU JYA HE Co., Ltd. (HLJH) have been focusing on manufacturing and marketing the industrial lubricants more than 30 years. Our fundamental belief is to make a harmful, friendly with lives, businesses, and leaving a lasting legacy for generations to come. We offer metalworking fluids (water-based cutting fluid, neat cutting oil), rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain. Our fundamental belief is to offer harmful and friendly products such as water-based cutting oils, neat cutting oil, rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain.

HLJH has been offering customers high-quality metalworking oils and fluids, both with advanced technology and 39 years of experience, HLJH ensures each customer's demands are met.