Aluminum Cutting fluid

The Optimal Solution for Enhanced Efficiency and Surface Stability

In the aerospace, automotive, and precision component industries, aluminum alloys have long been a mainstream material thanks to their lightweight properties and high ductility. However, their high thermal conductivity and strong tendency to adhere to cutting tools also present significant challenges on the shop floor. To ensure stable quality while improving production efficiency, choosing a cutting fluid specifically formulated for aluminum is one of the most critical decisions.

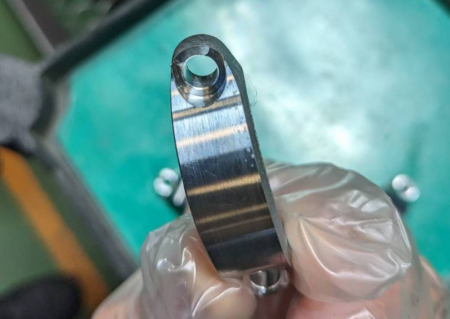

Hai Lu Jya He’s aluminum cutting fluid series is engineered to solve common issues encountered in high-speed CNC machining, such as localized heat buildup and chip adhesion on tools. These fluids are particularly effective in machining aerospace structural components, automotive aluminum housings, and die-cast aluminum parts. After adopting our aluminum series, many customers have seen a significant reduction in tool wear and surface roughness fluctuations, alongside real gains in yield and throughput.

For instance, a southern Taiwan-based aerospace machining company previously suffered from frequent chip clogging and whitening on aluminum workpieces during milling operations, resulting in a scrap rate as high as 10%. Within just three weeks of switching to Hai Lu Jya He’s AIE-329 cutting fluid, the scrap rate dropped to 2%, tool life increased by 30% on average, and expendable supply costs were reduced by over 15%.

In addition to stable performance, Hai Lu Jya He also offers a practical “Cutting Fluid Selection Guide” tailored for various aluminum applications, helping manufacturers quickly identify the most suitable formulation. For hard aluminum alloys such as 7075, we recommend fully synthetic cutting fluids to ensure stable lubrication and cooling performance at high speeds. For common grades like 6061, semi-synthetic options offer the best balance between performance and cost-effectiveness.

What Are the Key Characteristics of Aluminum Cutting Fluids?

Due to aluminum’s fast heat conductivity, high surface reactivity, and softer structure, machining often results in localized overheating, accelerated tool wear, and surface roughness issues. A premium cutting fluid must have excellent lubricity to form a stable oil film between the tool and the workpiece, reducing metal-to-metal contact and heat accumulation, which in turn prevents chip adhesion and extends tool life.

Effective cooling is also essential. While aluminum dissipates heat quickly, high-speed CNC milling generates heat faster than it can be removed, leading to part expansion or dimensional distortion. Hai Lu Jya He’s cutting fluids are designed to efficiently transfer heat into the fluid medium, stabilizing dimensional accuracy and improving product consistency.

Post-machining, aluminum surfaces are prone to white spots or discoloration when exposed to air and humidity, especially if the cutting fluid lacks adequate protective properties. To address this, our formulations include antioxidants and corrosion inhibitors that form a protective layer after machining, preserving both surface brightness and structural integrity.

From a formulation standpoint, aluminum-specific fluids should avoid sulfur- and chlorine-based extreme pressure additives, which can cause corrosion. Hai Lu Jya He’s products use neutral, non-toxic formulations that are environmentally friendly, highly emulsifiable, and resistant to microbial degradation—ensuring long-term stability. In high-speed operations, our low-foam design prevents bubbles from blocking coolant flow or clogging filters, making your production line safer and more efficient.

What Are Common Issues in Using Cutting Fluids for Aluminum Machining?

Even when using the correct aluminum cutting fluid, poor maintenance practices can lead to various issues. The most common is unpleasant odor, typically caused by poor water quality or bacterial growth from uncleaned fluid tanks. This degrades both the work environment and fluid performance, potentially leading to corrosion on aluminum parts.

Another frequent issue is white haze or uneven discoloration on the machined surface. This can be due to high pH levels or unstable formulations—especially those containing chlorinated ingredients or used with soft water—leading to surface oxidation and poor adhesion during subsequent anodizing or plating.

At high spindle speeds, fluids lacking anti-foam properties may generate excessive bubbles due to agitation, resulting in unstable spray patterns, inconsistent cooling, and coolant overflow. If not addressed, this can directly affect machining rhythm and equipment operation.

Some customers also report excessive residual oil films on aluminum parts that are difficult to clean, interfering with post-process inspections or measurements. These problems are often linked to poor emulsion stability, incorrect fluid concentration, or expired usage. When cooling and lubricity drop, tool life shortens, and machining precision becomes harder to maintain.

Though these issues may seem complex, they can be significantly mitigated by selecting the right fluid, managing concentration levels properly, and conducting regular tank maintenance. Hai Lu Jya He offers on-site fluid testing, technical inspection services, and user training programs to help manufacturers upgrade their fluid management systems and establish a stable, reliable machining environment.

If you're considering switching cutting fluids or looking to improve scrap rates and tool longevity in aluminum machining, Hai Lu Jya He invites you to complete our consultation form. Our technical team will recommend the best-fit aluminum cutting fluid based on your specific application needs, helping you build a more efficient and stable production workflow.

Aluminum Cutting fluid - The Optimal Solution for Enhanced Efficiency and Surface Stability | Taiwan-Based Metalworking Fluid Manufacturer & Supplier For 39 Years | HLJH

Located in Taiwan, HAI LU JYA HE CO., LTD has been an industrial lubricant manufacturer and supplier. Main products, include Aluminum Cutting fluid, metalworking fluids, industrial lubricants, soluble cutting oils, semi-synthetic cutting oils, synthetic cutting fluids, neat cutting oils, rust preventive oils, slideway oils and hydraulic oils, which can reach 150 tons of cutting fluids per month.

HAI LU JYA HE Co., Ltd. (HLJH) have been focusing on manufacturing and marketing the industrial lubricants more than 30 years. Our fundamental belief is to make a harmful, friendly with lives, businesses, and leaving a lasting legacy for generations to come. We offer metalworking fluids (water-based cutting fluid, neat cutting oil), rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain. Our fundamental belief is to offer harmful and friendly products such as water-based cutting oils, neat cutting oil, rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain.

HLJH has been offering customers high-quality metalworking oils and fluids, both with advanced technology and 39 years of experience, HLJH ensures each customer's demands are met.