MORESCO Water Soluble Cutting Oil

MORESCO BS-9 Water Soluble Cutting Oil

MORESCO BS-9 water soluble cutting oil is a premium quality water-soluble cutting oil which contains 50% to 80% mineral oil and forms a milky emulsion while mixed with water.

MORESCO BS-9 water soluble cutting oil has superior cooling and lubricating properties, and it contains rust corrosion inhibitor and biocide to prevent bacterial growth in emulsion systems. It's worth noting that MORESCO BS-9 used an eco-friendly formula without chlorine additives.

MORESCO BS-9 water soluble cutting oil is good for a variety of cutting operations on ferrous and nonferrous metals, especially for aluminum alloys which can prevent the change of color effectively. It has excellent lubricating, washing and cooling abilities to remove chips immediately and reduce the stickiness from surface, tools and workpieces.

As a manufacturer and supplier of metalworking fluids, we always give you the best and suitable advice for your reference. The SDS, TDS and product certifications of MORESCO BS-9 cutting fluid are all available upon request through the "Files Download" button.

Apart from that, we also offer tailor-made products (OEM/ODM) - OEM/ODM services ensure that lubricants are custom-engineered to align perfectly with machine design, enabling enhanced precision, accuracy, and surface finish.

Ready to take your machinery's performance to the next level? Contact us today to discuss your requirements, or place an order. Our team of experts is dedicated to assisting you in finding the perfect cutting fluid solution tailored to your needs.

Recommended for a variety of cutting operations on ferrous and nonferrous metals, especially for aluminum alloys. MORESCO BS-9 soluble cutting fluid can effectively preventing the change of color in aluminum alloys. Besides, it is best in hard materials, like tungsten steel, high manganese steel, stainless steel, iron, casting iron and titanium.

MORESCO BS-9 is used for lathe, boring, milling, drilling, tapping, threading, reaming, grinding operations, especially best in heavy cutting process. It is recommended to use 7– 8% concentrations for all types of operations. (Adjust according to the situation)

Feature

- Good for non-ferrous metals and aluminum material

- Excellent anti-corrosion effect to non-ferrous metal, especially aluminum alloys which prevents color changed

- Non chlorine, PRTR free

- Excellent cooling and lubricity

- Excellent extreme pressure protection

- Extended tool and wheel life

- Operator friendly and clean running.

Health & Safety

- This product is not expected to cause health concerns when used for the intended application and according to the recommendations in the Safety Data Sheet (SDS)

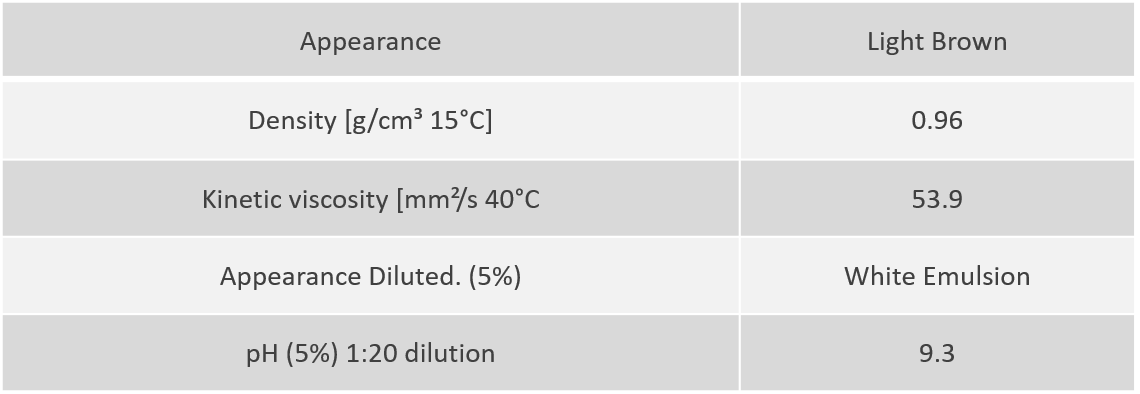

Specification

- Pail: 18 Liters (5 Gallon)

- Drum: 200 Liters (50 Gallon)

Storage Guidelines

- Storage: Avoid direct sunlight, under normal temperature, keep in a dry and cool place

- Expiration Date: 9 months (Base on brand-new)

- Substances floating on the coolant may be seen in the beginning of use. They are antifoaming additive and disappear in a couple of days.

- Download Files

Technical Data Sheet (TDS) of MORESCO BS-9

A Technical Data Sheet is a document which describes the technical data of a raw material. It is important for our use of the material in the intended...

DownloadSafety Data Sheet (SDS) of MORESCO BS-9

Protect health and security and also a duty to properly label substances on the basis of physio-chemical, health or environmental risk. (Date Prepared:2020.09.01)

DownloadProduct Certifications of MORESCO BS-9

Product certification confirms that a product meets the necessary local, national or international quality standards relevant to a particular market or product...

Download- Extended Article

Water Soluble Cutting Fluid Vs. Neat Cutting Oil: Choosing The Right Solution For Metalworking

When it comes to CNC lathe machining, choosing the right cutting oil is crucial. Water-based cutting oil and oil-based cutting oil are two common options....

MORESCO Water Soluble Cutting Oil - MORESCO BS-9 cutting fluid has the excellent cooling, washing, lubricating performances. | Eco-Friendly, Harmless & Low Pollution Industrial Lubricants Manufacturer And Supplier Since 1982 | HLJH

Located in Taiwan, HAI LU JYA HE CO., LTD has been an industrial lubricant manufacturer and supplier. Main products, include MORESCO Water Soluble Cutting Oil, metalworking fluids, industrial lubricants, soluble cutting oils, semi-synthetic cutting oils, synthetic cutting fluids, neat cutting oils, rust preventive oils, slideway oils and hydraulic oils, which can reach 150 tons of cutting fluids per month.

HAI LU JYA HE Co., Ltd. (HLJH) have been focusing on manufacturing and marketing the industrial lubricants more than 30 years. Our fundamental belief is to make a harmful, friendly with lives, businesses, and leaving a lasting legacy for generations to come. We offer metalworking fluids (water-based cutting fluid, neat cutting oil), rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain. Our fundamental belief is to offer harmful and friendly products such as water-based cutting oils, neat cutting oil, rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain.

HLJH has been offering customers high-quality metalworking oils and fluids, both with advanced technology and 39 years of experience, HLJH ensures each customer's demands are met.