What’s the Difference and How to Choose the Right Hydraulic Oil?

Industrial lubricants - hydraulic oil AW32, AW46, AW68

When selecting hydraulic oil, you’ll often come across three common anti-wear grades: AW32, AW46, and AW68. But what do these numbers mean, and how do you choose the best option for your machinery? Is a higher number always the better choice?

This guide explains the key differences between these essential grades, walks you through the right selection process, and highlights the critical risks of using the wrong viscosity.

What Does “AW” Stand For? “AW” stands for Anti-Wear

This means the hydraulic oil contains specialized additives designed to reduce metal-to-metal wear in high-pressure hydraulic systems.

AW oils are the industry standard, widely used across demanding applications such as:

■ CNC machinery

■ Automation equipment

■ Hydraulic presses

■ Heavy industrial systems requiring reliable performance under sustained load.

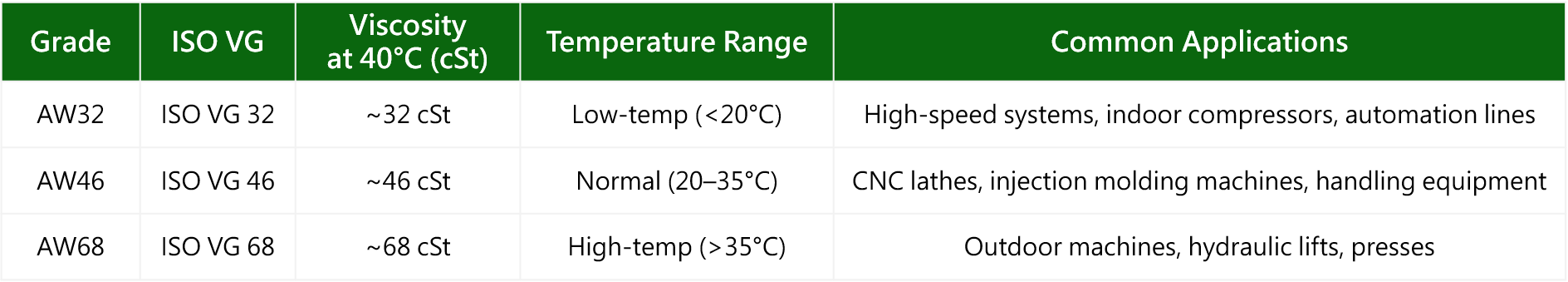

AW32, AW46, and AW68: The Viscosity Difference

The main difference between AW32, AW46, and AW68 hydraulic oils lies in their viscosity—a measure of how thick or thin the fluid is at a specific temperature. In general, the higher the number, the higher the viscosity. Thicker oils (like AW68) are better suited for higher operating temperatures or heavier-duty systems, while thinner oils (like AW32) perform better in colder environments or lighter applications.

Hydraulic Oil Grades & Applications

These hydraulic oil grades correspond directly to the ISO VG (International Standards Organization Viscosity Grade) classification system. Each number reflects the oil’s kinematic viscosity, measured in centistokes (cSt) at 40°C, which is a critical factor in hydraulic fluid performance and system efficiency.

How to Choose the Right Grade: 3 Key Factors

Selecting the correct hydraulic oil depends on three key factors: temperature, equipment specs, and workload.

1. Ambient Temperature (Where the Machine Operates)

| Environment | Recommended Grade | Why |

| Cold or refrigerated | AW32 | Flows easily at low temperatures |

| Indoor/temperature-stable | AW46 | Balanced choice for standard factory use |

| Hot or outdoor settings | AW68 | Maintains protective film in high heat |

2. Equipment Specifications (Check the Manual)

Always refer to your equipment’s OEM (Original Equipment Manufacturer) manual before selecting a hydraulic oil. Many systems—especially those with high-speed, high-precision, or pressure-sensitive components—are designed to operate within a narrow viscosity range. Using a fluid outside these specifications can reduce efficiency, cause premature wear, or even void the equipment warranty. Following the manufacturer's guidelines ensures optimal performance, component protection, and longer service life.

3. Operating Pressure & Speed (System Load)

■ High Pressure, Low Speed: Use higher viscosity (e.g., AW68) to maintain protection under extreme force.

■ High Speed, Frequent Cycling: Use lower viscosity (e.g., AW32 or AW46) for faster response and less heat buildup.

Critical Risks of Using the Wrong Hydraulic Oil

Using the wrong hydraulic oil viscosity can have a significant negative impact on your system’s performance and longevity. If the oil is too thin, it may result in low system pressure and insufficient lubrication. On the other hand, oil that’s too thick can cause the system to overheat, respond sluggishly, and work harder than necessary—leading to increased wear and tear on critical components over time. To avoid these issues, it’s essential to consult your equipment manufacturer's specifications and use a reliable hydraulic oil viscosity chart when selecting the appropriate ISO VG grade for your application.

Final Tip: Always Choose Based on Application

Viscosity isn’t one-size-fits-all. Choosing the right AW hydraulic oil protects your equipment, maximizes efficiency, and reduces maintenance costs. When in doubt:

✅ Check your equipment manual

✅ Review environmental conditions

✅ Use an accurate viscosity chart

☎️ Need Personalized Advice? +886-25332210

Contact our technical team today for a free consultation and personalized recommendation tailored to your specific equipment and operating conditions. Fill out the form below to connect with a specialist!

- Recommend Product

WILL Hydraulic Oil AW-32

High-Performance Anti-wear Oils ISO 32

WILL AW-32 Hydraulic Oil is a shear-stable and high-quality lubricant which is formulated with...

DetailsWILL Hydraulic Oil AW-46

High-Performance Anti-wear Oils ISO 46

WILL AW-46 Hydraulic Oil is a high quality lubricant manufactured from refined paraffin base...

DetailsWILL Hydraulic Oil AW-68

High-Performance Anti-wear Oils ISO 68

WILL Hydraulic Oil AW-68 is a top-tier industrial lubricant, specifically formulated to deliver...

Details- Articles

In automated and industrial machinery, the hydraulic system is often regarded as the heart of the operation—and hydraulic oil (or hydraulic fluid) is the lifeblood that keeps it running smoothly. Unfortunately,...

Read more