Brass & Copper

Common Issues in Copper Processing and Cutting fluid Selection

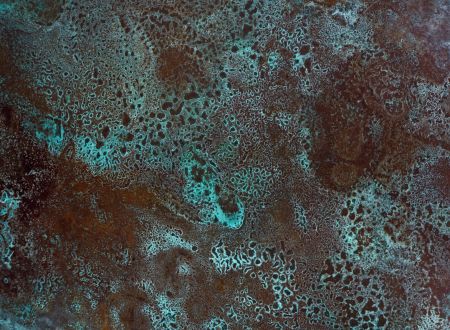

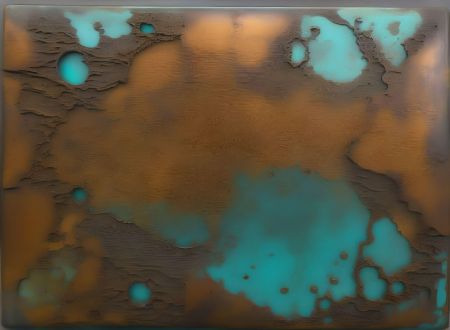

Copper and brass materials are widely used in various industrial applications, such as musical instruments and sculptures. A common issue with these materials is the formation of a green substance on the surface, caused by the reaction between copper and environmental oxygen and moisture, leading to the creation of copper patina. For example, the green color on the Statue of Liberty is a result of this reaction.

Similarly, during copper cutting, the cutting fluid may turn green due to a chemical reaction between copper and the fluid's components. Although this change is harmless to humans, selecting the appropriate cutting fluid and maintaining good working habits can significantly reduce this phenomenon.

Cutting Fluid Turning Blue-Green color

When cutting copper materials, the cutting fluid in the tank often turns blue-green. This is due to copper's soft texture, high density, and susceptibility to oxidation and corrosion. Copper easily reacts with other metals and certain components in the cutting fluid, resulting in the formation of copper patina and copper rust, which causes the fluid to change color.This discoloration mainly arises from the formation of copper patina. While it doesn't affect the cutting function, it requires timely cleaning to prevent stains on the workpiece surface.

Copper's high density and oxidation properties make it prone to releasing copper ions during the cutting process. These ions combine with components in the cutting fluid, such as certain amines or organic substances, resulting in a noticeable blue-green color. Although this discoloration doesn't directly affect cutting performance, failing to clean it regularly can lead to stains on the workpiece surface, impacting the final product quality. Regular inspection and replacement of the cutting fluid, as well as maintaining cleanliness in the tank and work area, can effectively minimize this issue.

Stability of Cutting Fluid During Copper Processing

Copper is very sensitive to the pH value of cutting oil, so when using water-based cutting fluid, it is crucial to select a product with strong hard water resistance and a pH level that is not too high. A suitable water-based cutting fluid can effectively remove copper chips, prevent adhesion, and ensure the smoothness and processing quality of the workpiece surface. Regular pH monitoring during processing is essential to maintain the stability and performance of the cutting fluid. If the pH is too high, it can cause copper corrosion, affecting workpiece quality; if too low, it can lead to bacterial proliferation, compromising the fluid's stability and lubrication.

Choosing the right water-based cutting fluid for copper processing is critical. These fluids should have excellent hard water resistance to maintain stable performance. Copper's soft texture and tendency to oxidize make it prone to releasing copper ions during cutting, which can react with components in the fluid, leading to discoloration or degradation. Therefore, selecting a cutting fluid with strong hard water resistance can effectively reduce these reactions, ensuring the fluid's stability and longevity.

WILL AIE-75 Semi-Synthetic Cutting Fluid for Copper Processing

WILL AIE-75, offered by Hai Lu Jya He, is an eco-friendly, chlorine-free semi-synthetic cutting fluid specifically designed for copper processing. This product boasts excellent cleanliness and antibacterial properties, effectively inhibiting bacterial growth. During processing, it easily removes copper chips, preventing adhesion.

Brass & Copper - Common Issues in Copper Processing and Cutting fluid Selection | Taiwan-Based Metalworking Fluid Manufacturer & Supplier For 39 Years | HLJH

Located in Taiwan, HAI LU JYA HE CO., LTD has been an industrial lubricant manufacturer and supplier. Main products, include Brass & Copper, metalworking fluids, industrial lubricants, soluble cutting oils, semi-synthetic cutting oils, synthetic cutting fluids, neat cutting oils, rust preventive oils, slideway oils and hydraulic oils, which can reach 150 tons of cutting fluids per month.

HAI LU JYA HE Co., Ltd. (HLJH) have been focusing on manufacturing and marketing the industrial lubricants more than 30 years. Our fundamental belief is to make a harmful, friendly with lives, businesses, and leaving a lasting legacy for generations to come. We offer metalworking fluids (water-based cutting fluid, neat cutting oil), rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain. Our fundamental belief is to offer harmful and friendly products such as water-based cutting oils, neat cutting oil, rust preventive oil, hydraulic oil, slideway oil, spindle oil, gear oil and so on that cover the whole industrial lubricant value chain.

HLJH has been offering customers high-quality metalworking oils and fluids, both with advanced technology and 39 years of experience, HLJH ensures each customer's demands are met.